Each condition to be monitored during an inspection - for example, temperature, weight, etc. - is defined as a Quality Detail. Quality Details are the individual points you record during an Inspection. The range of acceptable values or critical limits which must be adhered to for each monitored condition is also defined in the quality detail card.

Creating a Quality Detail

To create a new quality detail, the process is as follows.

-

Open the Quality Details List and create a new entry.

The Quality Detail Card will open. -

Set value to field Code as the unique identifier for the quality detail.

The Code for a Quality Detail is a maximum of 20 characters. -

Fill in Name and Description, which can be longer then the Name.

-

The Type field is the most important one:

-

Set Real Number if this inspection can be registered as a number.

-

Set Grade to register a numeric rating or grade.

-

Set Reference if the inspection result is one out of a list of possible responses.

-

Set Yes/No if this inspection is a condition that is either fulfilled or not.

-

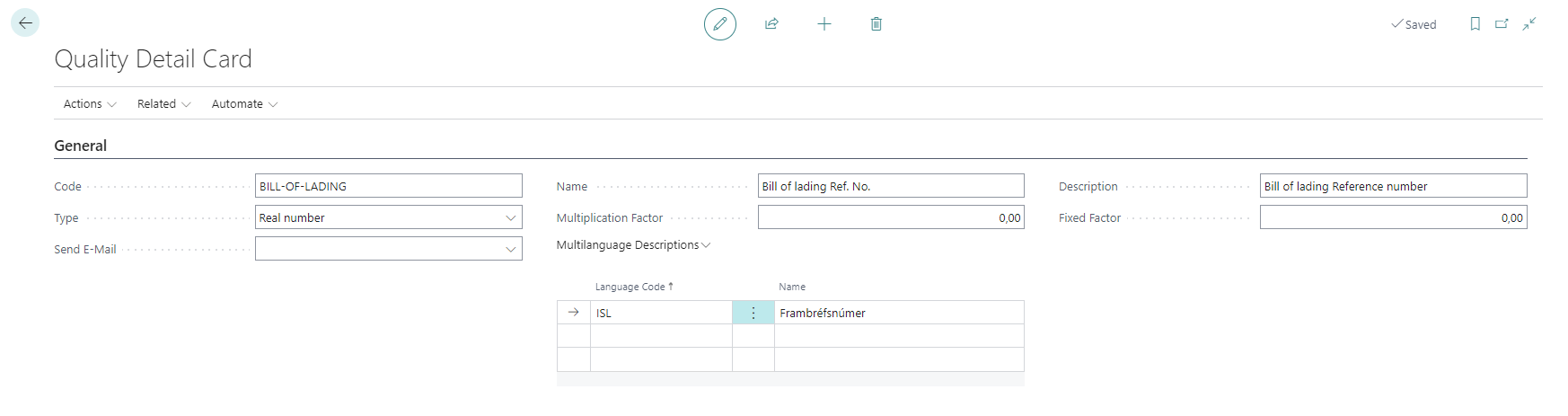

Set Text to register a specific alphanumeric information.

For example: The inspection may require the entry of a Bill of Lading reference number, which could be numerical or alphabetical, or a combination of both.

-

-

In the Multilanguage Descriptions you can indicate an alternate name for the item in different languages. These are selectable in printing some Quality Reports so that the appropriate language can be used if sending the report to a foreign customer. Drill in to the Language field and choose the Language which will be used. Then enter the alternative descriptive Name for the item in that language.

-

According to the value of the Type field, finalize the setup card, different fields are required;

-

For Real Number, click on the Real Number tab to define the acceptable ranges for the value.

See https://wisefish.atlassian.net/wiki/spaces/WFQU/pages/edit-v2/70090790#Real-Number-Quality-Items below to continue. -

For Type Grade, click on the Grade/Reference tab to set the parameters.

See https://wisefish.atlassian.net/wiki/spaces/WFQU/pages/edit-v2/70090790#Grade-Quality-Items below to continue. -

For Type Reference, click on the Grade/Reference tab to set the parameters.

See https://wisefish.atlassian.net/wiki/spaces/WFQU/pages/edit-v2/70090790#Reference-Quality-Items below to continue. -

For Type Yes/No, click on the YesNo tab to set the parameters.

See https://wisefish.atlassian.net/wiki/spaces/WFQU/pages/edit-v2/70090790#Yes%2FNo-Quality-Items below to continue. -

For Text quality details, no additional fields are required.

-

See field list below for a description of every field.

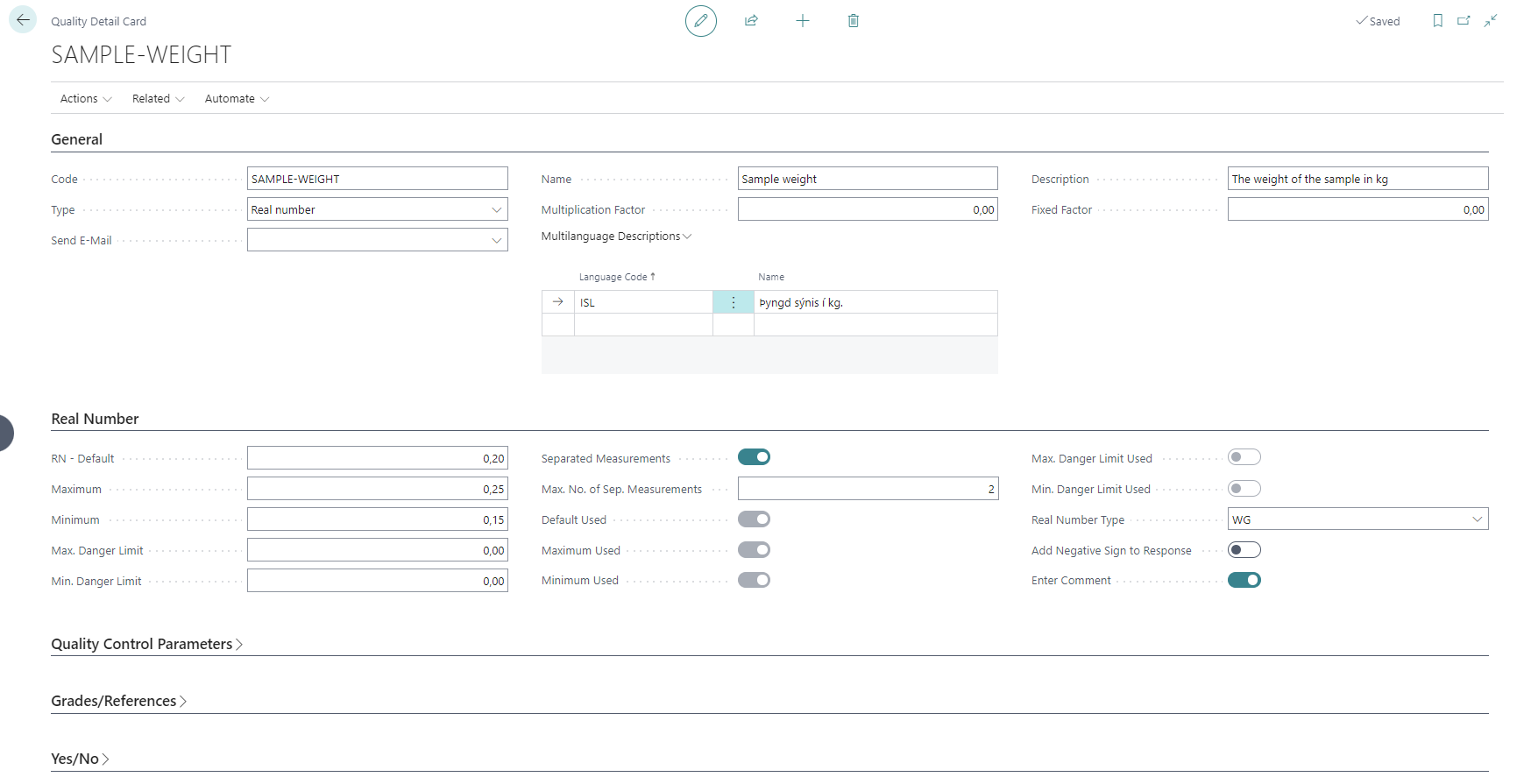

Real Number Quality Detail

To continue populating the card when Type is Real Number:

-

In the RN- Default field, enter the default value to automatically appear when recording a quality inspection (i.e. if you are recording a temperature value and you would like the default value to be 32 degrees, enter the number 32 here).

-

Set the normative Minimum and Maximum allowable range for this item. When you are recording a quality inspection, the system will notify you of the minimum/maximum allowable values.

-

If desired, enter a sub-set minimum and maximum range to alert you when a parameter has exceeded the normative range (Min. and Max. Danger Limit fields). When a quality inspection is recorded, the system will notify that the danger limit has been reached or exceeded. Danger limits must be outside the minimum and maximum range entered above.

-

If desired, you can define the measure unit that the number entered is meant to indicate (degree, percentage, etc.). Drill in to open the Real Number Type list and choose an entry or, if necessary, add a new one to the list.

-

If this inspection entry can be re-checked more than once during the course of the inspection without nullifying the validity of the inspection, place a checkmark in the Separated Measurements field and specify the number of times the item can (or should be) checked in the Maximum No. of Separate Measurements field.

-

If it is mandatory to enter a comment when the result of the inspection item is out of the minimum/maximum range, place a checkmark in the Enter Comment field.

For example, if normally a box being inspected contains ten pieces and each individual piece is to be weighed, then you could set the maximum number of allowable separate measurements to ten.

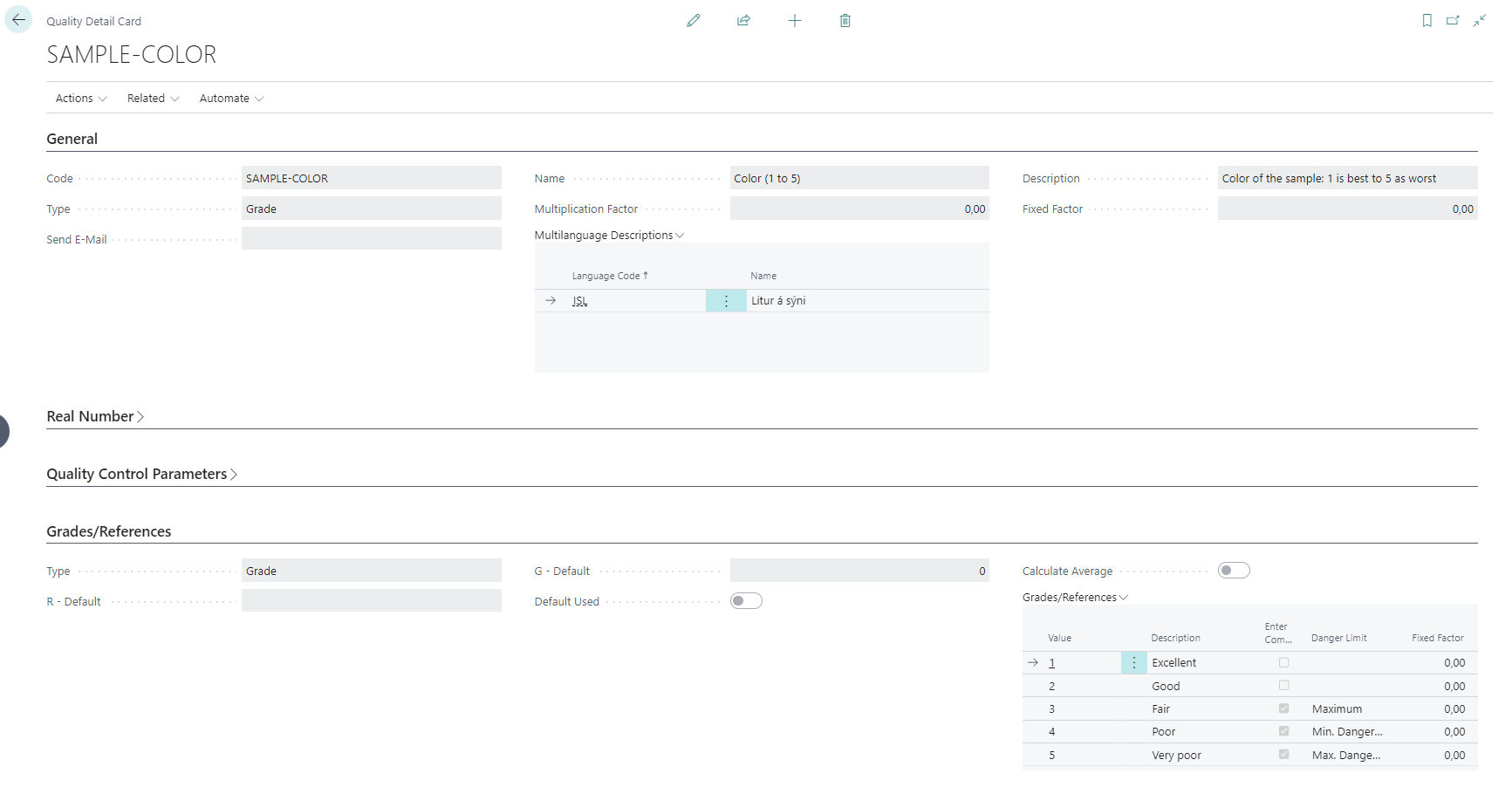

Grade Quality Detail

Grade is used when you want to record inspection results for this item as a numeric rating or grade.

If Type is Grade, fill out the following parameters on the Grade/References tab:

-

Create a range of possible grades which can be assigned to this quality item (one grade per line) in the Value field, together with a brief description of what the grade indicates in the Description field. The grade must be numerical and a maximum of 2 digits.

-

If desired, enter the default grade to display in the G - Default field. This is the normal grade this item would usually receive. You can also have the average to date value displayed during a quality inspection by placing a checkmark in the Calculate Average field.

-

If it is mandatory to enter descriptive comments along with the grade when the inspection is being performed, check the Enter Comments field.

-

Use the Danger Limit field to assign the acceptable range for the grade itemized. For example, if you assign a grade scale from 1 to 5 for an item, if the desired range is between 2 to 4, assign a grade of 1 as the Minimum Danger Limit, and a grade of 2 as the Minimum. When the item receives a grade of 1, it will fail the inspection for this item, whereas a grade of 2 will be the minimum acceptable grade for this item.

Example

The example below shows a grade scale of 1 to 5 (excellent to very poor). The Minimum Danger Limit is assigned to the grade of 3 (fair) and the Enter Comments field is checked. This means that when this quality item is checked in an inspection, if the item is given a grade of 3, the item is unacceptable and an explanatory comment must be entered. A grade of 2 for this item means that the item is in the minimum acceptable range.

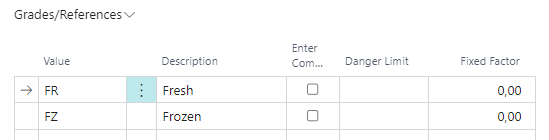

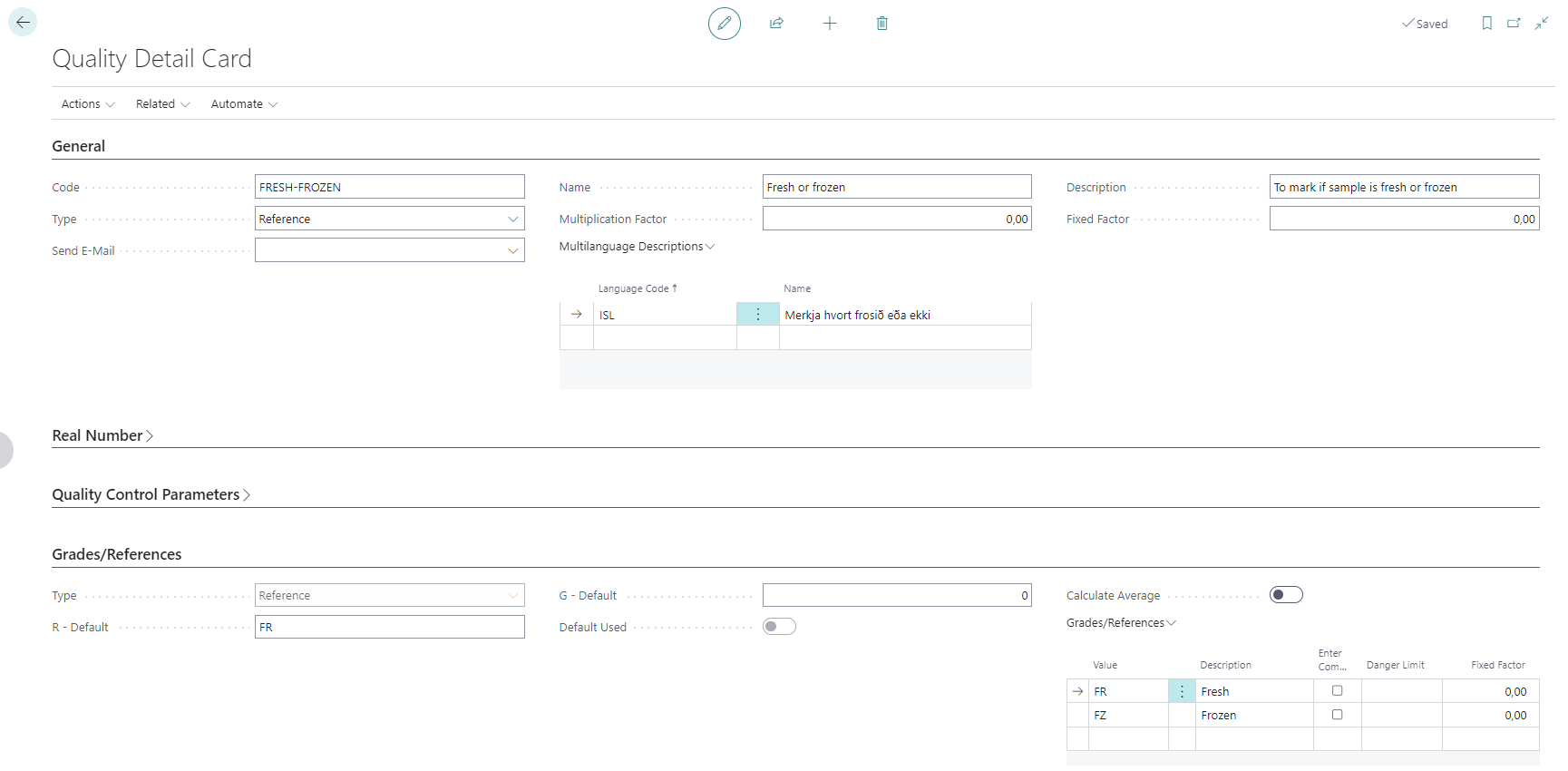

Reference Quality Detail

Reference is very similar to grade and is also used when you want to record inspection results for this item as one of a possible list of responses. The main difference is that a reference is not numerical but a text ranking.

If you have chosen Reference as your item Type, the following parameters should be defined on the Grade/References tab:

-

Create a line for each response you wish to have selectable for this quality item. For example, the following shows two possible references: Fresh or Frozen.

You can choose to make it mandatory to enter a comment when a reference is selected by checking the Enter Comments field and rank it according to a minimum/maximum range or a danger range.

-

If desired, enter the number of the default reference to display in the R - Default field. If specified, when performing this inspection, the default will be filled in automatically and would need to be changed if it is not correct.

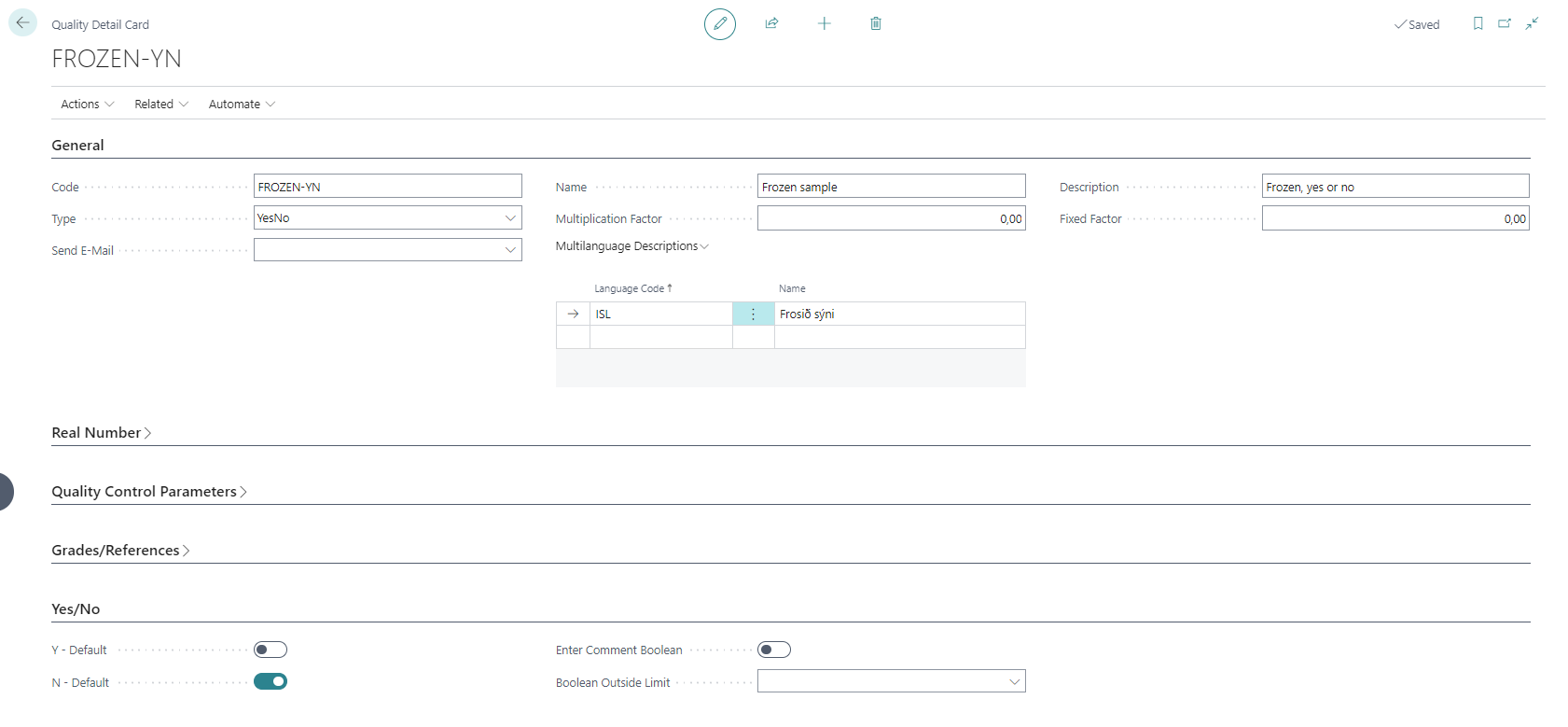

Yes/No Quality Detail

Yes/No is used if this inspection item is to check a single parameter to be fulfilled as a yes or no response. If you have chosen Yes/No as your item Type, the following parameters can be defined in the Yes/No tab (but are not mandatory):

-

To set a default value for the yes/no response, place a checkmark in the appropriate Y or N field. For example, if you are inspecting for the presence of foreign material, you would likely choose No to be the default value, and therefore would place a checkmark in the N - Default field.

-

Enter comment Boolean: As in the other quality item types, you can choose to make entering a comment mandatory when the response is selected.

-

Boolean Outside Limit, is to define if it yes or no that not desirable..

A Quality Detail with Type = Yes/No

Another example: To check for the presence of foreign material, it would likely be desirable to record an explanation of what material was found if the response was Yes. To do this, place a checkmark in the Enter comment Boolean field and choose Yes from the Boolean Outside Limit drop-down list to indicate that a comment must be entered upon selection of the Yes response. The system will then prompt the inspector to enter a comment when this response is selected.

Text Quality Detail

Text quality item types are used to require the inspector to enter specific alphanumeric information. For example, the inspection may require the entry of a Bill of Lading reference number, which could be numerical or alphabetical, or a combination of both. As there are no parameters or choices involved with this type of entry, it is simply set up on the General tab of the Quality Item card.

Copying a Quality Detail

When setting up quality inspections, many of the quality details will be quite similar. Therefore, there is an action available to copy a Quality Detail and then user can make adjustments to it, rather than needing to set it up from scratch.

-

Display the Quality Detail you wish to copy and click Copy Detail from the Action bar.

-

In the subsequent form, enter a unique value in New Code.

-

Choose whether you wish to also copy any designated Foreign Names, Marks and/or Comment Lines, with the appropriate checkmarks.

-

Click OK to complete the process.

The new Quality Item will now be displayed and ready to edit as required.

Quality Detail Card - Field list

General Tab

|

Field |

Description |

|

|---|---|---|

|

Code |

This is the unique identifier for the quality detail. |

Mandatory |

|

Type |

Defines a value category which inspection results for this item are to be recorded in. For example, temperature, time or weight is measured and recorded As an actual value whereas other items, such as smell or appearance, are generally quantified by defined terms.

|

Mandatory |

|

Name |

A short name, used widely in the module. |

Mandatory |

|

Description |

Set a brief description here for the quality detail. |

Mandatory |

|

Multilanguage Descriptions |

Alternate names in different languages. These are selectable in printing some Quality Reports so that the appropriate language can be used if sending the report to a foreign customer |

Optional |

|

Send E-Mail |

Specifies when email is sent accordoing to the defined limit. Options:

|

Optional |

|

Multiplication Factor |

Specifies the multiplication factor of the quality detail being recorded/viewed. |

Optional |

|

Fixed Factor |

Specifies the fixed factor of the quality detail being recorded/viewed. |

Optional |

Real Number

|

Field |

Description |

Mandatory/

|

|---|---|---|

|

RN- Default |

The default value to automatically set when recording a quality inspection (for example if you are recording a temperature value and you would like the default value to be 32 degrees, enter the number 32 here). |

Mandatory |

|

Maximum Minimum |

Set the normative allowable range for this item. When you are recording a quality inspection, the system will notify you of the minimum/maximum allowable values. |

Mandatory? |

|

Min. Danger Limit Max. Danger Limit |

To enter a sub-set minimum and maximum range to alert you when a parameter has exceeded the normative range. When you are recording a quality inspection, the system will notify you that the danger limit has been reached or exceeded. Danger limits must be higher than the maximum allowable range entered for this item and lower than the minimum allowable range. |

Optional |

|

Real Number Type |

To define the measure unit that the number entered is meant to indicate (degree, percentage, etc.). Drill down to choose an entry or, if necessary, add a new one into the list. |

Optional |

|

Separated Measurements |

Put a checkmark here if this inspection entry can be re-checked more than once during the course of the inspection without nullifying the validity of the inspection |

Optional |

|

Maximum No. of Separate Measurements |

To specify the number of times the item can (or should be) checked in the field. |

Optional |

|

Enter Comment |

Put a checkmark here, to enforce the user to add a comment when value is outside the limits. |

Optional |

Quality Control Parameters

|

Field |

Description |

|---|---|

|

Fat % |

Specifies the average fat % for this quality detail. |

|

Size from Size to |

Specifies the average size size for this quality detail |

|

Quality Comment |

Specify if quality comments should be recorded. |

Grades/References

|

Field |

Description |

|---|---|

|

Grades/References |

The list of options should be created here. |

|

R - Default |

The default for Type = Reference. |

|

G - Default |

The default for Type = Grade. |

|

Default Used |

Gets a checkmark automatically if a G - Default is selected, which must be one value from the list. |

|

Calculate Average |

Put a checkmark here to calculate an average for these deails for an inspection (which only works if there are multiple measurements, of course). |

Yes/No

|

Field |

Description |

|---|---|

|

Y - Default |

Put a checkmark here to set Yes as the default answer in inspections. |

|

Y - Default |

Put a checkmark here to set Yes as the default answer in inspections. |

|

Enter Comment Boolean |

To ask for a comment if inspection is not desirable. |

|

Boolean Outside Limit |

To define if it is yes or no that is not desirable. |

gæðaatriðalisti mælanleg gildi metin atriði