Zones and bins define the physical locations of items within the warehouse. A zone belongs to a location, which much exist in the standard Location list of BC. Then each zone is divided into bins.

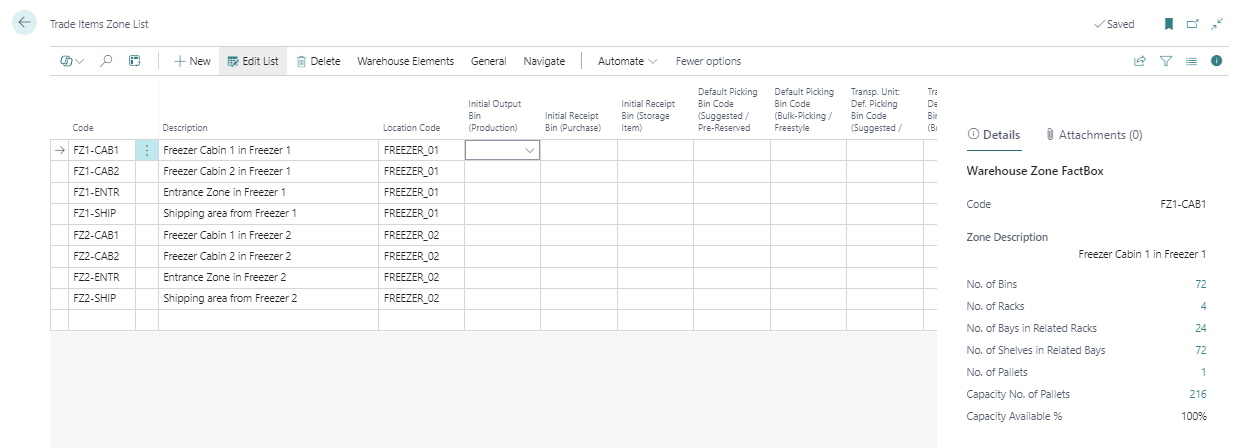

Trade Item Zone List

Zones have a specific role in the operation of a warehouse. They are necessary to distinguish between areas

where pallets and their related trade items are kept. For instance a zone can be specified where the storage of the goods take place in a designated storage room. A different zone can be specified where the dispatch and reception of the goods takes place. And so forth.

To search for the Zone setup list, type in “zone” in the search field (not “zones”)

The following columns are in the list:

|

Field |

Description |

|

|---|---|---|

|

Code |

The unique indentifier for the zone. |

|

|

Description |

The description. This will be shown in a number of places in the system. |

|

|

Location Code |

Each zone is connected to a specific Location Code. |

|

|

Bulk Area |

If this is a bulk organized area. |

|

|

Fields for default bins: Notice: The field "Reception Zone Code (Trade Item)" on the related location has to be assigned accordingly. |

|

|

|

Initial Output Bin (Production) |

Specifies an initial output bin to be used in the production process for pallets, as a suggested position in the circumstance where no bin has been assigned in advance.

|

|

|

Initial Receipt Bin (Purchase) |

Specifies an initial receipt bin to be used for pallets in the reception process of the corresponding purchase document, as a suggested position in the circumstance where no bin has been assigned in advance. Notice: The field "Reception Zone Code (Trade Item)" on the related location has to be assigned accordingly. |

|

|

Initial Receipt Bin (Storage Item) |

Specifies an initial bin for storage items to be used in the reception process of pallets, as a suggested position in the circumstance where no bin has been assigned in advance. Notice: The field "Reception Zone Code (Trade Item)" on the related location has to be assigned accordingly. |

|

|

Fields for picking process: |

|

|

|

Directed Path for Picking |

This field has the purpose to be able to distinguish when moving pallets & their related trade items between storage room (indicated by the Confirm-option) and entrance area (indicated by the Finalize-option) where the picking is to be finalized. |

optional |

|

Directed Path for Picking |

The field has the purpose to be able to distinguish when moving pallets and their related trade items between storage room (indicated by the Confirm-option) and entrance area (indicated by the Finalize-option) where the picking is to be finalized. |

optional |

|

Default Picking Bin Code (Suggested / Pre-Reserved TIs) |

Specifies a default picking bin to be used in the picking process of pallets with suggested / pre-reserved trade items. |

|

|

Default Picking Bin Code (Bulk-Picking / Freestyle Reservation) |

Specifies a default picking bin to be used in the picking process of pallets using the bulk-picking / freestyle reservation method. |

|

|

Transp. Unit: Def. Picking Bin Code (Suggested / Pre-Reserved TIs) |

Specifies a default picking bin for transport units, to be used in the picking process of pallets with suggested / pre-reserved trade items. |

|

|

Transp. Unit: Def. Picking Bin Code (Bulk-Picking / Freestyle Reservation) |

Specifies a default picking bin for transport units, to be used in the picking process of pallets with suggested / pre-reserved trade items. |

|

Even if the zone belongs to a Location, the Code of the zone must be unique globally, so no two locations cannot have the same zone list. Therefore something that identifies the location is often put as first part of the Zone Code, for example if there are 2 locations with freezers, freezer 1 and freezer 2 - and both have a cabin numbered 1, the zones could be named like this:

-

FZ1-CAB1 : Freezer Cabin 1 in freezer 1

-

FZ2-CAB1 : Freezer Cabin 1 in freezer 2

Warehouse Bins

Similar to zones in a warehouse, the bins have a specific operational purpose. The general idea of a bin is to support the warehouse management in its operations, to narrow the positioning of the pallet & its related trade items to such precision, where the need of spending time in a search of the related items should be eliminated (or at least diminished to minimal efforts). For instance, one shelve in a bay, placed in a rack located in a storage room, could be identified with a designated bin. A bin could also represent a position where the reception or dispatch takes place at the entrance area. The bin identity is in a form of unique individual code, which ideally would be utilized in barcode labels put on each position, which individual bin represents. Afterwards, the registration of the bin for the related pallet can therefore use barcode guns to assign the bin identity effortless, thus eliminating user errors in registration & minimize efforts in time-consuming work.

Bin Types

Each bin has a specific type. Following list of options are available:

-

Receipt & Put-Away – An area for the start position in the reception of the goods.

-

Load & Ship – An area for the final position before shipping the goods.

-

Storage – A position where the goods are stored.

-

Floor – An area for temporary placement of goods, without any unique visual positional attributes, other than the area itself on the floor.

-

Aisle – An area for temporary placement of goods, typically in a storage room between racks.

-

Gate Inbound – An area for temporary placement of goods, stored on their way from entrance area into a storage room.

-

Gate Outbound – An area for temporary placement of goods, stored on their way from storage room into an entrance area.

-

Outside Area – An area for temporary placement of goods, is only utilized at times when the warehouse has no other option than keeping goods in the outside area, whatever the reason might be (for example storage rooms in warehouse are full and/or staff pre-occupied with other things in higher priority).

-

Intermediate Area – An area for temporary placement of goods, used when no other previous option fits the role of the designated area.

Types that are not related the Storage-option, will be hereafter referenced as non-storage related bins. They will affect the behavior in the scanning of the pallets into bins. See chapter Warehouse Picking Pallet Worksheet

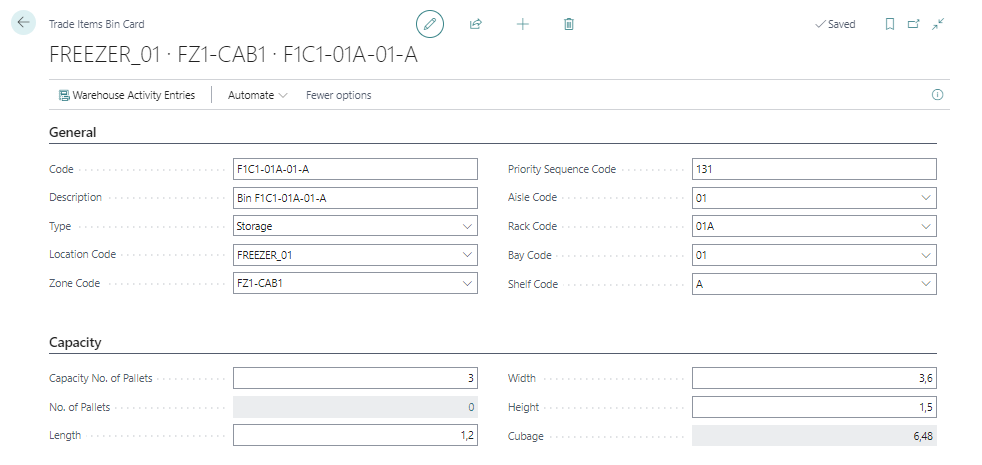

Trade Items Bin Card

Each bin has a setup card with the following tabs:

General

|

Field |

Description |

|---|---|

|

Code |

The unique indentifier for the zone. |

|

Description |

The description. |

|

Type |

This field has the purpose of identifying the role, which the bin serves for the operation of the warehouse.

|

|

Location Code |

The Location Code of the bin will be the same as for it’s zone. |

|

Zone Code |

The zone the bin belongs to. |

|

Priority Sequence Code |

Used to label the bin with higher ranking in priority, for example when picking. |

|

Aisle Code Rack Code Bay Code Shelf Code |

These fields are optional and only for informational purpose. |

Capacity

|

Field |

Description |

|---|---|

|

Capacity No. of Pallets |

The unique indentifier for the zone. |

|

Length

|

Fields to specify the volume of the bin. |

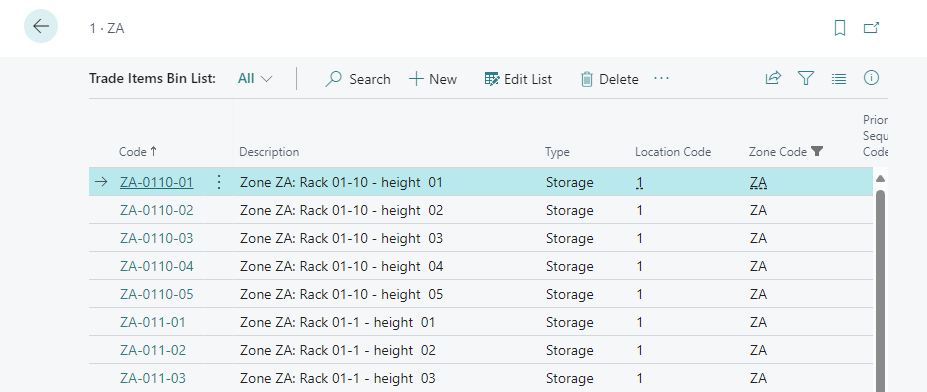

The code of every Bin must be unique globally in the system, so no two bins can have the same idendity. Therefore something that identifies the Zone is often put as first part of the Bin Code, for example if there is the same shelf numbering in two different storage rooms, for example:

-

Shelf 101

-

Shelf 102

-

Shelf 103

-

…etc.

The bins cannot be named 101, 102 etc, because something that identifies the storage room must be put in front of the Bin code, for example:

-

Code A-101 (Bin 101 in storage room A)

-

Code B-101 (Bin 101 in storage room B)

svæði sölueininga hólf